Choosing the right types of pallet material might not be the first thing on your mind, but selecting the most suitable type can transform how smoothly your operations run. And save you a whole lot of money in the process.

From timber that can handle heavy loads, to plastic for hygienic environments or metal for serious strength, each option has its place. And knowing which pallet to use, and when, helps you protect your products, maximise storage, and make smarter choices across your warehouse or supply chain.

As Perth’s pallet experts, Palletwest is here to guide you every step of the way. So keep reading to find out which pallet material is right for your business.

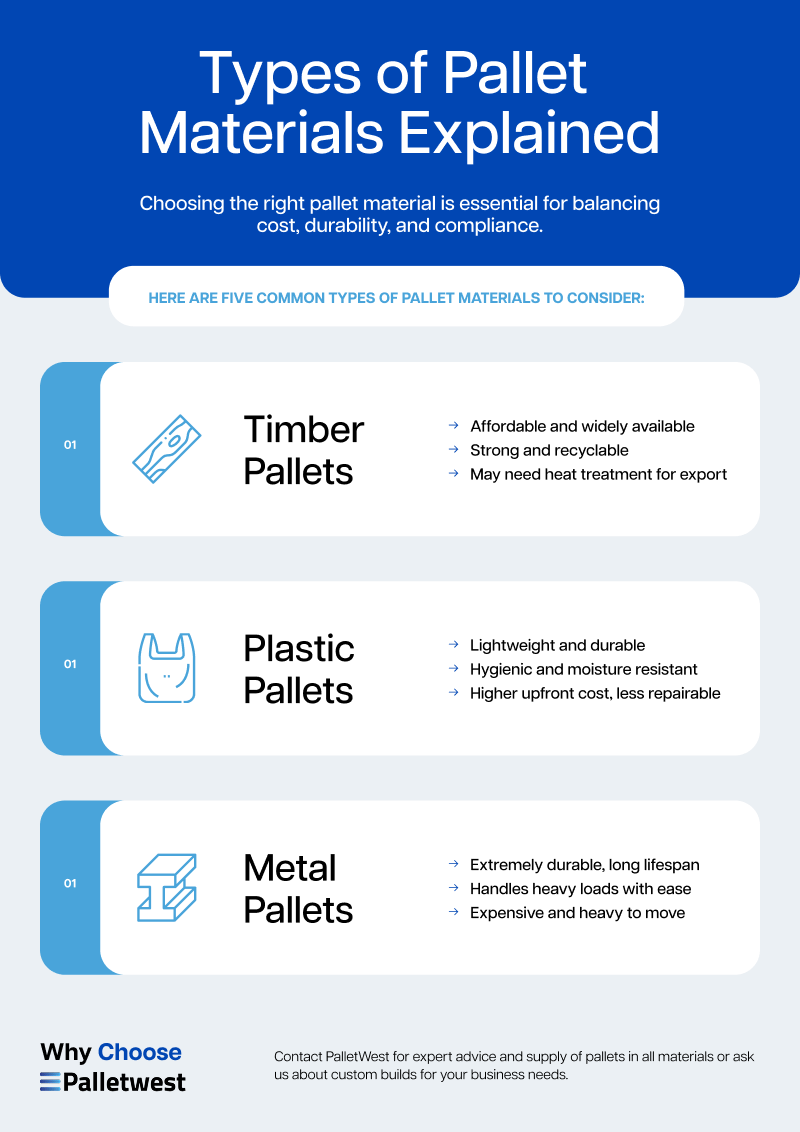

Comparing different types of pallet materials

Below, you’ll find a quick visual comparison of common pallets, breaking down the key differences between timber, plastic and metal, making it easier to spot which one fits your operations best.

1. Timber pallets

Wooden pallets are the classic go-to choice for a good reason. They’re versatile, strong and widely accepted across industries. You’ll find them in everything from warehouses and factories to shipping yards.

One of their biggest advantages is that they can handle heavy loads while remaining cost-effective. And if they get damaged, repairs are simple compared to other types of pallet materials.

Let’s take a look at the pros and cons of timber pallets for your business:

Pros

- Affordable and widely available: A major advantage of timber pallets is that they’re easy to source. This makes them a practical choice for businesses of all sizes.

- High-load capacity: Hardwood pallets can carry heavy products and they’re sturdy enough for stacking, which is a great way to maximise your available space.

- Easy to repair and recycle: Damaged planks or boards can be replaced without having to discard the entire pallet.

- Industry standard: Timber pallets are widely used across warehouses, transport and shipping systems, so you rarely run into compatibility issues.

Cons

- Vulnerable to moisture and pests: If you store timber pallets outside or in damp conditions, they can wrap, rot or attract termites.

- Can splinter or crack: Over time or under heavy use, timber can develop splinters or cracks, which could damage goods or create safety hazards for you.

- Heavier than plastic alternatives: Moving and handling timber pallets requires more effort and may increase transport costs.

What they’re best suited for

- Businesses that need a balance of strength and cost-efficiency, like manufacturing, warehousing and general logistics.

- Companies that prefer repairable pallets over single-use options.

2. Plastic pallets

Plastic pallets are becoming an increasingly popular choice for industries where hygiene, consistency and durability are non-negotiable. The reason for this is that, unlike timber, they don’t absorb moisture.

That means they’re far less likely to harbour bacteria, mould or pests. This is what makes them a perfect choice for clean or regulated environments.

Here’s a look at the advantages and drawbacks of plastic pallets for your business:

Pros

- Lightweight and easy to handle: Staff can move them around with less effort, which makes manual handling safer and quicker.

- Moisture and pest resistant: They don’t warp, rot, or attract termites, even if they’re stored outdoors or in damp areas.

- Easy to clean: They can be washed or sanitised regularly. This makes them excellent for food, pharmaceutical and chemical environments.

- Long lifespan: Built to last through repeated use, giving you great value over time.

- Consistent dimensions: Unlike timber, plastic pallets keep their shape, making stacking and automated systems hassle-free.

Cons

- Higher upfront cost: Plastic pallets cost more to buy than timber. But their longer lifespan can make them worth it.

- Tricky to repair: Plastic pallets are hard to fix, and once they crack or break, unfortunately replacement is usually the only option.

- Environmental impact: Making plastic pallets has a bigger footprint than timber, so sustainability can be a concern.

Who plastic pallets work best for

- Food and beverage producers handling perishable items that must meet strict hygiene standards.

- Pharmaceutical and chemical companies that need pallets compliant with regulatory requirements.

- Exporters or businesses shipping internationally who need lightweight, uniform pallets that travel well.

3. Metal pallets (steel/aluminium)

Yes — metal pallets exist, and they’re built for serious heavy lifting. Made from steel or aluminium, they offer incredible strength, durability, and resistance to fire and weather. You’ll often find them in industries like mining, steel production, or construction, where extreme loads and safety standards leave no room for compromise.

That said, metal pallets come with a hefty price tag and are often overkill for everyday business operations. They’re heavy, costly to transport, and not the most practical option for most warehouse or logistics setups.

At Palletwest, we don’t specialise in metal pallets; we focus on other pallet materials better suited to most business needs. Most Perth businesses get better value and performance from our timber, plastic, and export pallet options, which are:

- More cost-effective – giving you reliable performance without the high upfront cost.

- Lighter and easier to handle – ideal for day-to-day warehouse use.

- Durable and compliant – meeting hygiene, safety, and export requirements across a wide range of industries.

If you’re after strength, affordability, and versatility — our team can help you find the right pallet solution that keeps your operations efficient and cost-conscious.

Expert advice from Palletwest

Choosing the right pallet materials isn’t just about picking one type — it’s about balancing cost, functionality, and flexibility to suit your operations. Here’s what our team at PalletWest recommends:

- Choose materials that balance cost efficiency and functionality.

Making informed decisions ensures your operations remain economical, safe, and effective. - Mix pallet types for greater versatility.

A blend of timber, plastic, and export pallets helps businesses handle different day-to-day needs more efficiently.

⚬ Timber pallets – ideal for heavy, in-warehouse loads and cost-effective handling.

⚬ Plastic pallets – perfect for hygienic or regulated environments where consistency and cleanliness matter.

- Match each pallet to the task at hand.

This protects your products and staff while helping control costs and save storage space. - Seek expert guidance.

Palletwest has helped countless Perth businesses choose the right pallet combinations, design custom solutions, and secure reliable supplies. Our experience ensures you get the best mix of strength, hygiene, and value for your operation.

Find the right pallets for your business

You don’t have to guess when it comes to choosing the right pallet material. At Palletwest, we help Perth businesses like yours select the perfect mix of plastic, metal and composite pallets, whether it’s for everyday warehouse use, export shipments or specialist needs.

From choosing the perfect pallet type to custom builds and consistent delivery, our team ensures your products stay protected and your operations stay seamless.

So get in touch today to explore your options and see how the right pallets can make a serious difference for your business.